The Best Guide To American Plastics

Some Known Incorrect Statements About American Plastics

Table of ContentsAmerican Plastics - The FactsAmerican Plastics Fundamentals ExplainedSome Of American PlasticsThings about American PlasticsThe 5-Second Trick For American Plastics

Larger jobs might call for pipes with greater sizes to successfully distribute fluids over long ranges. Factors such as terrain trouble, the possibility for environmental stress, and the setup environment ought to influence the pipeline size to make sure a successful, enduring application.

Engage with expert suggestions to verify your option and adjust as needed for optimal results. Armed with this expertise and the workable steps described, you are well-equipped to make informed decisions when choosing HDPE pipeline sizes for your projects. Your interest to information in this option process will certainly go a lengthy method in making certain the performance, safety, and cost-effectiveness of your piping systems.

A Biased View of American Plastics

HDPE pipelines are widely taken on across a range of markets due to their adaptability and strength. One of the most usual usages for HDPE pipe is in water supply systems.

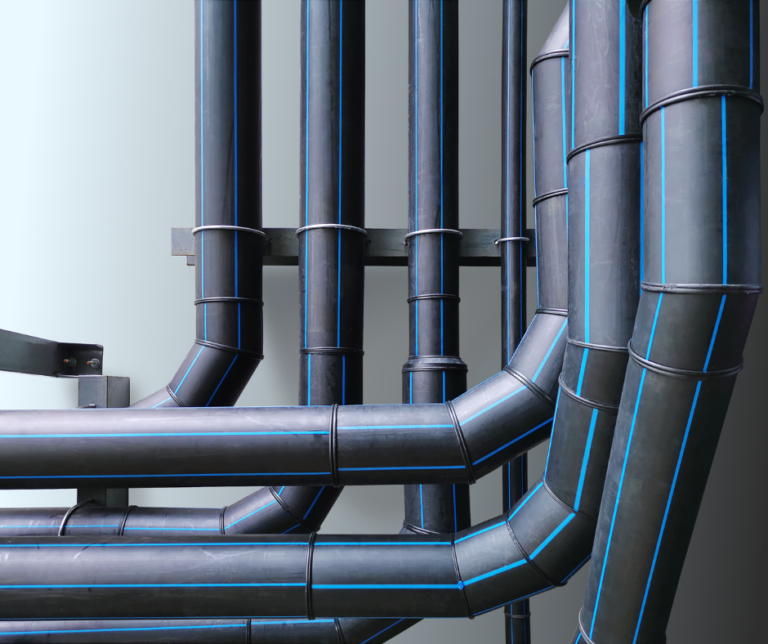

: HDPE pipes are signed up with via warm blend, creating a seamless, identical connection as solid as the pipe itself. This watertight joint is critical in gas and water distribution, where leakages can cause unsafe scenarios or costly waste.: HDPE pipes are lighter than typical steel pipes, making them simpler to transfer and install.

Our easy and fast ordering process and effective logistics ensure you obtain your 4-inch HDPE pipe in the fastest feasible time (Texas hdpe pipe manufacturer). Our after-sales team is readily available 24/7 to help with any concerns you may come across, making certain peace of mind.

For instance, PE 80 is for straightforward commercial applications like gas and water, while PE 100 uses long-term strength and performance for tougher usages. For a succinct check out applications, below are several of the most typical sorts of HDPE piping and their applications. Piping systems make use of PE 32 or PE 40 for low-pressure applications.

Little Known Questions About American Plastics.

PE 80 has a product resistant to splits, so it's suitable in applications vulnerable to cracking, like sewer system and water circulation lines. PE 100 is also resistant to fractures, and 100 N/mm2 is the minimum needed toughness. As stated, categories of HDPE piping consist of nominal pressure, product, and color coding.

Producers create pipes with various stress qualities (PN grades). This reveals the pressure in bars the pipeline can support with water at 68 levels Fahrenheit. The pressure qualities follow European criteria, and they are: PN 2.5 max pressure 2.5 bar PN 4max stress 4 bar PN 6max stress 6 bar PN 10max pressure 10 bar PN 16max pressure 16 bar The shade codes that suggest the pressure grade are yellow for PN4, red for PN6, blue for PN10, and eco-friendly for PN16.

Pipe why not try these out providers use sizing overviews with extra details like wall density and mass. Quality control complies with ISO criteria regulating the product layout and minimum necessary stamina (MRS) of pipes.

Industries think about small pressure, product, and various other elements when figuring out which pipes to utilize - high quality hdpe pipe. Today, you'll see high-density polyethylene pipelines in water supply, gas circulation, agriculture, and far more. Industries make use of PN 10 grade HDPE pipeline for water supply and distribution networks. You'll typically see it in multistory home facilities.

Things about American Plastics

It's worth keeping in mind that gas requires high tolerance to pressure, making PN-16 to PN-2 grade pipes suitable for operations. The agriculture market utilizes HDPE pipelines for watering and drainage. On top of that, HDPE is appropriate for sewage, mining, and the telecom sector. Thanks to piping, cities can handle sewer and stormwater to avoid flooding.

Mining companies utilize pipes for slurry transportation and dewatering. The best part is that organizations can utilize general PN course pipelines for this application.

For starters, HDPE pipelines are incredibly long lasting and can last a lengthy time with very little upkeep. They're additionally immune to deterioration, chemicals, and UV rays. https://danecoffman79701protonme.mailchimpsites.com/. HDPE pipelines are additionally economical contrasted to various other piping products. They're much less susceptible to damage, which cuts repair expenses! HDPE pipelines are lighter than conventional pipelines for better handling and transport.

Get This Report on American Plastics

Whether you're a professional, engineer, or DIY lover, this article will provide you with the understanding to make enlightened choices and attain optimum outcomes. When it pertains to picking the best HDPE pipeline for your project, recognizing the PSI ranking is of utmost value. The PSI ranking measures the strength and stress capacity of the pipe, showing how much pressure it can endure without failure.

The PSI ranking of an HDPE pipeline identifies its capacity to manage different pressure degrees. Pipelines with higher PSI ratings can withstand higher pressure, making them appropriate for applications that involve greater fluid or gas stress. On the other hand, pipes with reduced PSI rankings are perfect for low-pressure applications.